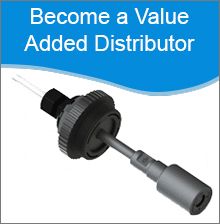

Series 20 Level Switch

The Series 20 pump controller product group from Compac Engineering Inc. is designed to handle industrial control jobs like switching contactors and solenoid valves. Our 20 series pump controls are valuable in AC or DC industrial control applications where compact size, corrosion resistance, long life, and repairability are essential pump controller factors. +/- Read More

How Does a Pump Controller Work?

The 20 series water pump control uses the Yaskawa Control Bestact hermetically sealed switch element. A magnetic float rides up and down a double-welded, molded stem containing the Bestact switch, and the contaminate-free hermetically sealed envelope keeps fumes and particles from interfering with switch reliability. Hinged armatures, wrought contacts and a wiping action are added to make reliable inductive load switching possible. Even under difficult conditions, long service can be expected.

Modes of Operation

The 20-611 pump control switch is offered as either a normally open or normally closed switch. Since the unit can be mounted threads up or threads down, merely specifying NO or NC is insufficient because we do not know what your “normal” is. The product is identified at the end of the stem “WET OPEN” or “DRY OPEN.” This signifies behavior according to the following definition:

- Wet open: pump control switch opens as the float approaches the hex and closes as the float approaches the stop ring at the opposite end.

- Dry open: pump controller switch opens as the float approaches the stop ring and closes as the float approaches the hex at the opposite end.

Features:

- Inductive load switching: The Series 20 pump controller uses the Bestact switch expressly created to switch inductive loads such as solenoid valves, contactors and starters. This is important because most industrial control circuits involve inductive loads when switched by changes in liquid level.

- Easy installation: 20s are available as standard devices with a variety of ways to attach the device to a tank structure. Threads, flanges and jam nut hardware provide a stock selection of adaptation choices.

- Nothing special: The Series 20 pump controller considers virtually any switch position or stem length as being standard. That’s because Compac doesn’t use a threaded attachment to connect an extended stem/float assembly to the housing. Instead, we use set screws and seal, the assembly with a 0-ring. This permits the customer to cut the stem to the length required, at the assembly site.

- Spare parts are now meaningful: No other product of the 20s class is designed with field assembly, disassembly or repair in mind. The Series 20 pump controller can be assembled in five or ten minutes, and part replacement repairs are equally fast.

Don’t take our word for it. The best way to get acquainted with a new product is to get a sample and try it out. If you want to evaluate the Series 20 pump controller please don’t hesitate to ask for a free sample. Call us today: 800-828-9044

General Specifications

* A number in brackets indicates the number of products in that specific category.